Making Cider is a Family Tradition

November 7, 2020

Making Apple Cider is a Family Tradition.

Money might not grow on trees, but apples do. And those sweet, tart, and delicious fruit can be easily turned into the country-life staple known as apple cider. Want to learn how to make your own? We spent the day with Greta’s family to learn the secrets of turning apples into cider and how to store that juice for later in the year.

Safety First

Before crushing and preserving apple cider, Oregon State University Extension Services has a free document to help you safely extract and preserve fruit juices. Download the free document Fruit Juices and Apple Cider to get started.

Select the Right Apples

The Ropp family’s orchard produces Gala, Fuji, Golden, Jonagold, and McIntosh. Other varieties you can use to make apple cider include Delicious, Rome, and Gravensteins. Try to avoid using too many smaller variety apples as the extra acids can affect the flavor.

Coastal tip: Want a tarter cider? Add one or two Granny Smith apples for every 100 apples. To get a darker cider, add some red delicious.

Grind up the Apples

You’ll want to wash and rinse your apples before grinding. The Ropps place their apples in a large water trough with clean water to rinse off the dirt and a capful of bleach to kill off any bacteria. Then, it’s off to the grinder. This releases the juices from the apples.

To grind your apples at home, you can use a food processor.

Everything is collected in large, plastic buckets and then poured into press bags.

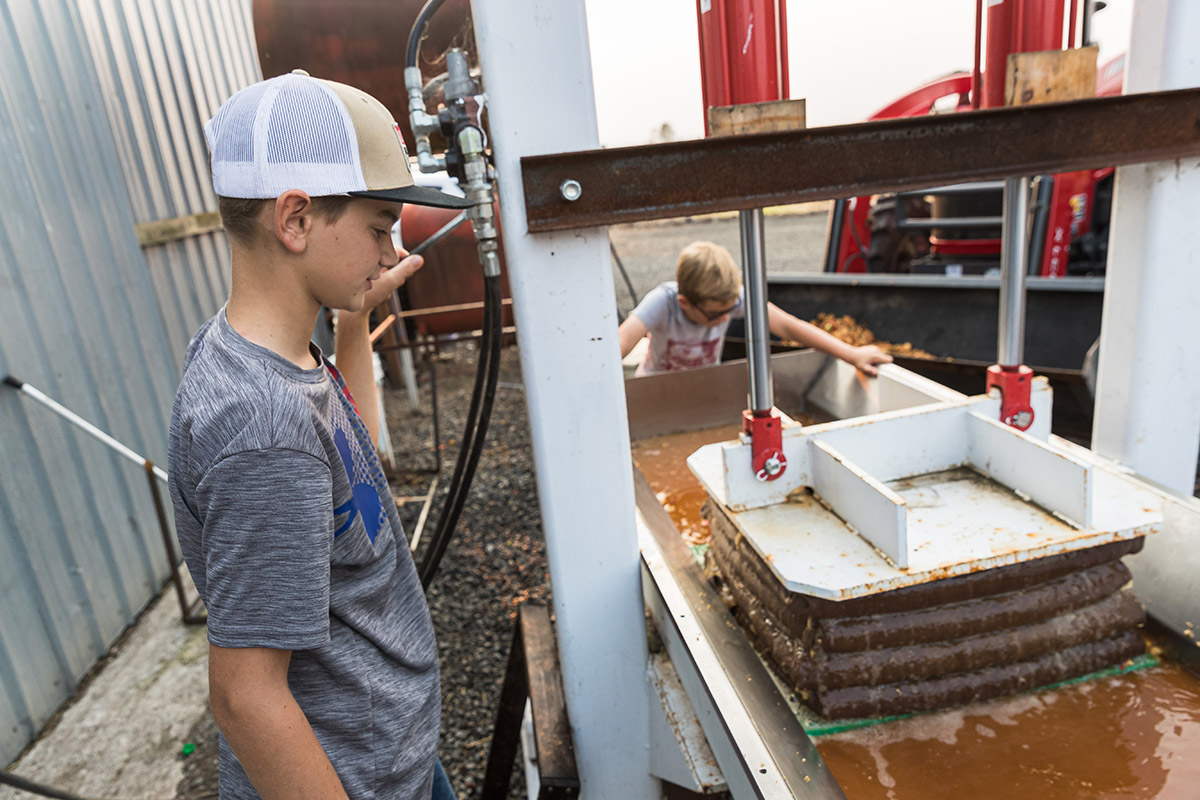

Once in the press bag, they move it to their home-made cider press. Using even pressure, they extract the juice from all the chopped apples. The juice that comes out is cloudy in appearance. The juice is collected in clean buckets.

When doing a small batch at home, use a strong jelly bag and a rolling pin. Press slowly and steadily and squeeze by hand. Be careful, as the bag can break.

Using a cheesecloth, the crew strains the juice into large containers. This allows all the juices to mix and mingle to make a more balanced cider.

All of the chopped bits of apple are fed to the cows and added to the composter.

The final step for the Ropp family is to fill 1-gallon jugs with their cider. This year, they filled 500 1-gallon jugs. As it goes into each jug, it is filtered one more time to remove even more bits and pieces.

Leaving 2-inches of headspace at the top, they cap each jug and freeze them for later. Once opened, the juice needs to be used in a handful of days.

Coastal tip: Unpasteurized apple cider can be linked with illness caused by E. coli bacteria. To kill off any harmful bacterial, heat your juice to 160º F before canning or freezing.

Preserving and Canning

Apple cider can be canned. OSU suggests heating cider to 210ºF, pouring the hot juice into jars and processing in a boiling water canner. Process pints and quarts for 5 minutes, and half gallons for 10 minutes. After processing, take the canner off the heat, remove the lid and wait 5 minutes before removing your jars.

We’re Just What the Country Needs

You’ll find everything you need for your country lifestyle at your Northwest owned and operated Coastal. That includes hunting and fishing gear, work clothes, fashions for the whole family, footwear, livestock supplies, fencing, and feed. Stop by today.